Built on the values of reliability and quality,

Star Steels is one of the leading manufacturers of Steel Products in Ghana and West Africa.

We have become one of the most trusted suppliers to the construction industry in Ghana. With a production capacity of over 500 MT per day, Star Steels can provide consistent and dependable supply for your projects.

Star Steels manufactures quality steel that is compliant not only with Ghanaian standards, but also with international standards. Given our management’s rich experience in specialised steelmaking globally, we bring world- class levels of service and quality to Ghana.

We are one of Ghana’s few integrated manufacturers – with full control over the steelmaking process – right from scrap up to finished products. Our in-house melt shop allows us to monitor chemistry and quality from the beginning up to the end.

500 MT

Production capacity per day

300 Years

Run by an international team of professionals with a cumulative experience of more than 300 years in the metals manufacturing industry

Products

Star Steels produces a variety of steel products used in the construction, fabrication, and engineering industries.

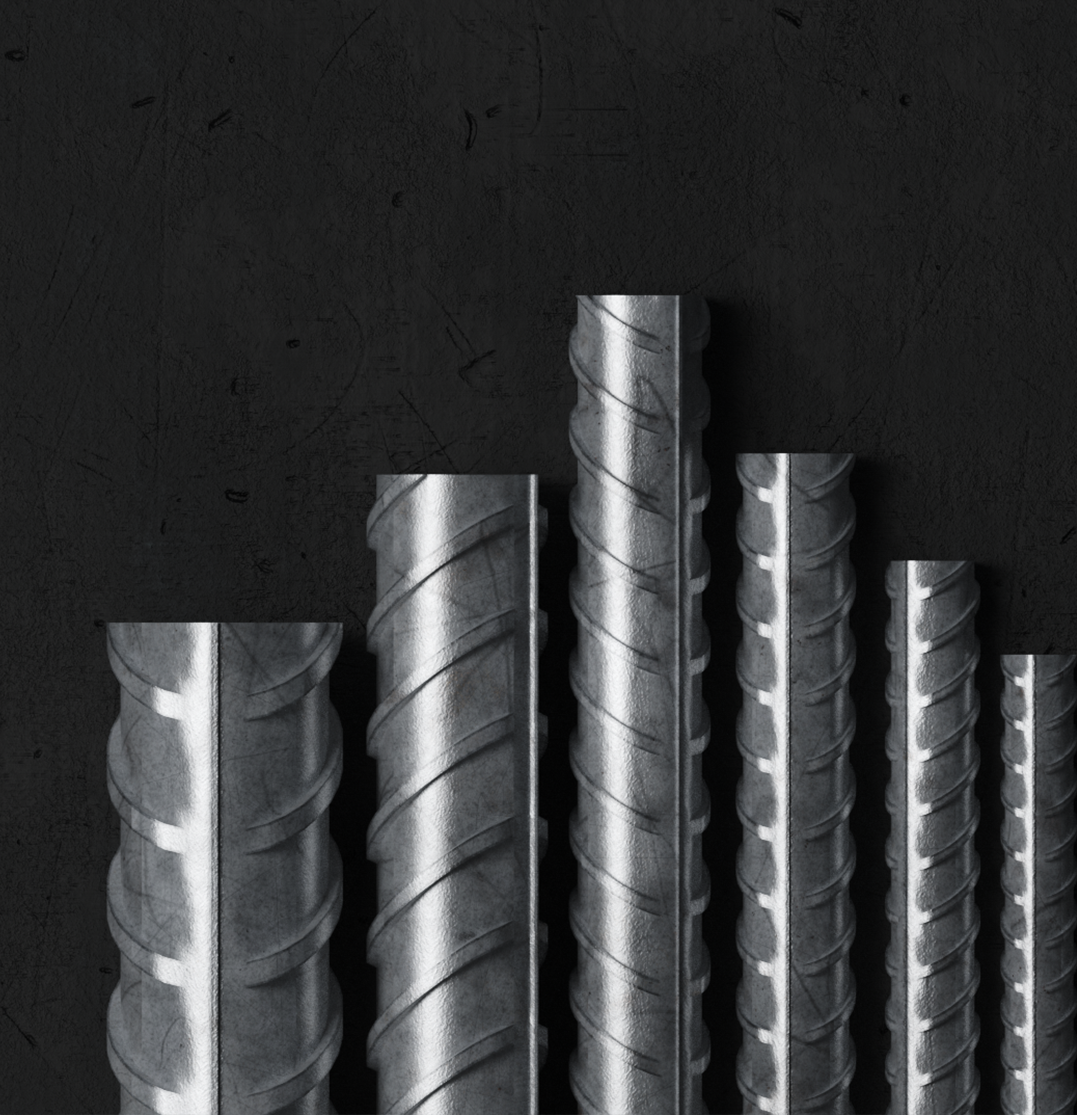

Star TMT (High Tensile) Rebars

Star Steels’ primary product is its unique High Tensile Star TMT Rebar. With tightly controlled chemistry, thermomechanical treatment, Star TMT stands out from other steel rebar and provides enhanced safety for your buildings.

Size Range:

- Diameter: 8, 10, 12, 16, 20, 25, 32 mm

Length: 12 meters

Other sizes available upon request

All sizes comply with Ghanaian standards and are subject to allowed tolerances

Chemical Composition:

| Carbon (C) | Manganese (Mn) | Sulphur (S) | Phosphorus (P) |

|---|---|---|---|

| 0.30% max | 0.60% min | 0.05% max | 0.05% max |

Physical Properties:

Yield Strength: 500 N/mm2 (Minimum)

Ultimate Tensile Strength: 550 N/mm2 (Minimum)

Elongation: 14% (Minimum)

Thermomechanical Treatment (TMT):

The TMT quenching process increases the strength of the rebar. Through water-cooling, the material’s surface layer is converted to a strong, tough, tempered martensite while the core remains ductile. Star Steels uses stateof- the-art, patented German technology for its quenching process.

Wire Products

Star Steels is one of the leading manufacturers of steel wire products in Ghana. Manufactured using state of the art machinery, our wire products are a symbol of strength and durability.

Binding Wire

Whether you need it for securing rebar in construction projects or for bundling and packaging, our binding wire provides reliable performance and ease of use.

Common Nails

Our common nails are designed to provide superior holding power and durability, making them perfect for a wide range of construction and woodworking applications.

Sizes Available:

1 inch to 5 inches in length

Features :

- • Excellent tensile strength

- • High resistance to corrosion

- • Flexible and easy to handle

- • Uniform thickness and smooth finish

Grinding Media Balls

Star Steels manufactures durable and efficient forged grinding media balls to meet the demands of the mining industry.

Our forged grinding media balls are engineered to provide optimal performance in the grinding processes of mining operations. These balls are essential for ensuring efficient and effective grinding of ores, leading to higher productivity and better extraction rates.

Comparison Chart

| Properties | Star TMT | Other Rebar |

|---|---|---|

| Integrated Production | Full control over melting and rolling quality | Not all rebars in Ghana are manufactured by a fully integrated process |

| Thermomechanical Treatment | Every rebar undergoes thermomechanical quenching for enhanced strength | May have lower tensile strength due to the absence of the quenching process |

| Bendability | Star TMT Rebar can be bent and rebent without cracking or any surface defects | Many rebar can crack under bending and re-bending conditions |

| Weldability | Star TMT can be welded without any problems and displays high bond strength | Often rebar can crack at the point of welding if its chemistry is not properly controlled |

Production Process

Quality

In order to consistently manufacture steel bars that can withstand the roughest of environments and that exceed international quality standards, Star Steels Ltd. operates an in-house physical and chemical laboratory to continually monitor quality standards. Production samples are systematically tested periodically to ensure that they adhere to our stringent criteria.

Every product undergoes thorough testing, including chemical analysis and durability assessments, to ensure compliance with local and international standards. This ensures our grinding media and steel products can withstand tough conditions, delivering reliable performance. Our commitment to quality also extends to our service. We collaborate with clients to understand their needs, offering tailored solutions that enhance their operations. At Star Steels, quality is not just a promise; it’s our guarantee.

We test our production every 15 minutes to ensure that every piece of steel coming off our lines is of the highest quality. .

Responsibility

Star Steels aims to be a responsible citizen of Ghana and provide strength and safety not just through its steel, but also through its wider social efforts. In line with our commitment towards social responsibility, we conduct various programs to uplift the society of Ghana.

Environment:

As a recycling company, Star Steels uses waste scrap as its raw material – reducing its carbon footprint. Moreover, we have installed one of the largest fume extraction systems in the country, ensuring that all waste gases are properly cleaned and treated before they are released into the environment.

Education:

We believe that education is the backbone of every country’s socioeconomic growth and development. We conduct various programs for university students to visit our factory and learn about factory operations & steelmaking. Such practices will allow Ghana to slowly become self-dependant and reduce the need for expatriate workers.

Culture:

Along with the economy, culture is essential strength for any country. Ghana’s rich and diverse history is to be celebrated. We facilitate and sponsor various cultural programs for Ghanaian people to showcase their colourful history.